MIL-DTL-85667/3B

REQUIREMENTS:

Application criteria. The sleeve bolt shall be used to provide a precision net fit or controlled

interference fit. The sleeve bolts shall be used in accordance with the limitations MIL-B-85667/1.

The sleeve bolts shall not be degreased and cetyl alcohol shall not be removed before installation.

Companion and accessory parts. Nuts in accordance with NASM85730 shall be used with the

sleeve bolts.

Oversize bolts. First and second oversize sleeve bolts may replace MIL-DTL-85667/3 sleeve bolts

for first and second repair operations.

Installation. Installation shall be in accordance with MIL-HDBK-271/104.

Material. Pin material shall be CRES PH 13-8Mo (UNS S13800) age-hardenable steel in

accordance with AMS 5629.

Sleeve material shall be corrosion resistant steel, AISI 304 (UNS S30400), in accordance

with MIL-T-8504 (chemistry only) or ASTM A269 (chemistry only).

Heat treatment. Pin shall be solution treat in air, vacuum or inert gas atmosphere at 1700 ± 25°F

for one hour. Air or oil cool; when solution treating in a vacuum or inert gas

atmosphere, inert gas or nitrogen may be used for cooling. Material shall be

cooled at -100°F for two hours within 24 hours after solution treatment.

Precipitation harden 4 hours minimum at the highest temperature (950 - 1000°F)

necessary to achieve the required strength level. No subsequent stress relief is

permitted. However, low temperature embrittlement relief treatment may be used

if applicable. Pin hardness shall not be greater than 48 HRC.

Surface texture. Surface texture shall be 32 microinches Ra in accordance with ASME B46.1.

Coatings or surface treatment. Pin shall be dry-film lubricated in accordance with MIL-PRF-46010,

Type I, .0003 / .0005 thick.

Sleeve - None.

Lubricants. .0001 inch overspray allowed on head and threads. After application of dry lubrication,

the pin outside diameter and sleeve inside diameter shall be lubricated with cetyl alcohol in

accordance with MIL-L-87132 or equivalent.

Unless otherwise specified, all dimensions are in inches. Tolerances: Decimals ± .010, angles +2°.

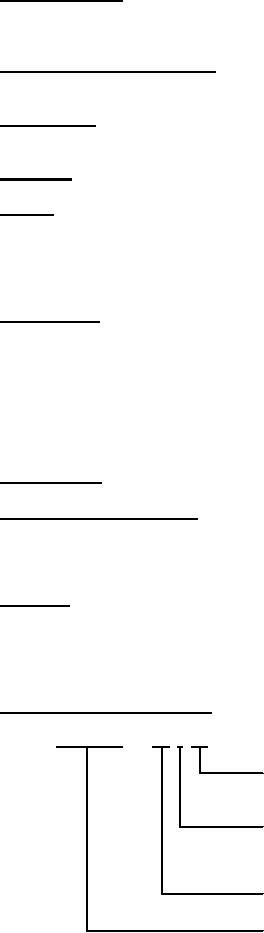

Example of military part number:

M85667/3 - 12 - 34

Grip length dash number in sixteenths of an inch.

(Stamp on threaded end.)

`-' designates basic shank diameter, X designates 1st

oversize, Y designates 2nd oversize. (Ink stamp on

sleeve when applicable.)

Diameter dash numbers in sixteenths of an inch.

Basic specification sheet number.

10