MIL-DTL-45912B

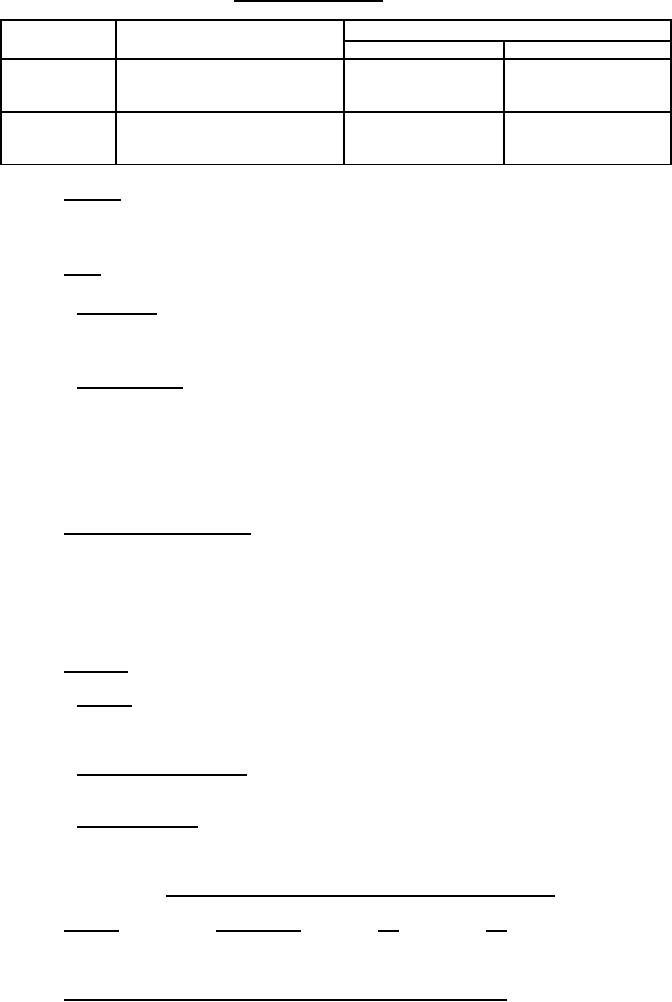

TABLE II. Mechanical Properties.

Bolt Size - Inches

Composition

Properties

Up to 1" Inclusive

Over 1"

Tensile Strength PSI Min

120,000

105,000

A

Proof Load PSI

85,000

74,000

Hardness Rockwell C Range

25-34

19-30

Tensile Strength PSI Min

150,000

150,000

B

Proof Load PSI

120,000

120,000

Hardness Rockwell C Range

32-38

32-38

3.5 Threads. Threads shall be UNC or UNF, class 2A, as specified on the applicable Military

standard in accordance with FED-STD-H28/2. Acceptability of threads shall be in accordance with

FED-STD-H28/20, system 22.

3.6 Head.

3.6.1 Head Taper. The taper of the head (angle between one side or sides of the head and the

axis of the fastener) shall not exceed 2 degrees, with the specified width across the flats being the

largest dimensions.

3.6.2 Bearing surface. The bearing surface of the head shall be at right angles to the axis of

the body within 2 degrees for bolt sizes up to and including one inch and within 1 degree for bolt

sizes larger than one inch. The bearing surface of the head shall be concentric with the axis of the

body within 3 percent of the maximum width across the flats. The diameter of bearing surface shall

be equal to 95 percent of maximum width across flats within plus or minus 5 percent.

4. VERIFICATION

4.1 Responsibility for inspection. Unless otherwise specified in the contract or purchase

order, the supplier is responsible for the performance of all inspection requirements as specified

herein. Except as otherwise specified in the contract or order, the supplier may use his own or

any other facilities suitable for the performance of the inspection requirements specified herein,

unless disapproved by the Government. The Government reserves the right to perform any of the

inspections set forth in the specification where such inspections are deemed necessary to assure

supplies and services conform to prescribed requirements.

4.2 Sampling.

4.2.1 Lot Size. A lot shall consist of all bolts of the same size, composition, protective finish

and thread produced under essentially the same conditions and submitted for inspection at one

time.

4.2.2 Sampling for examination. A random sample of bolts shall be taken from each lot in

accordance with Inspection Level II of ASQ Z1.4.

4.2.3 Sampling for tests. A random sample of bolts shall be taken from each lot in

accordance with Table III. Any bolt which fails to pass any of the tests shall be a defective and

cause for rejection of the entire lot represented.

TABLE III. Sample Size and Acceptance Rejection Number for Test.

Lot Size

Sample Size

AC

RE

2 50

2

0

1

51 500

3

0

1

501 35000

5

0

1

35000 over

8

0

1

4

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business