MIL-DTL-85667/7B

REQUIREMENTS:

Application criteria. The sleeve bolt shall be used to provide a precision net fit or controlled interference fit.

The sleeve bolts shall be used in accordance with the limitation of MIL-B-85667/1. The sleeve bolts shall

not be degreased and cetyl alcohol shall not be removed before installation.

Companion and accessory parts. Nuts in accordance with NASM85730 shall be used with the sleeve bolts.

Oversize bolts. First and second oversize bolts may replace MIL-DTL-85667/7 sleeve for first and second

repair operations.

Installation. Installation shall be in accordance with MIL-HDBK-271/104.

Material. Pin material shall be nickel alloy 718 in accordance with AMS5662 (UNS N07718). Pin shall be

cold worked and aged to 220 ksi Ftu and 125 ksi Fsu.

Sleeve material shall be corrosion resistant steel, AISI 304 (UNS S30400), in accordance with

MIL-T-8504 (chemistry only) or ASTM A269 (chemistry only).

Heat treatment. Pin shall be precipitation hardened (aged) only, in accordance with AMS 5662 to develop

the properties specified herein. Hardness shall not be greater than 50 HRC.

Surface texture. Surface texture shall be 32 microinches Ra in accordance with ASME B46.1.

Coatings or surface treatment. Pin shall be dry-film lubricated in accordance with MIL-PRF-46010, Type I,

.0003/.0005 thick.

Sleeve None.

Lubricants. .0001 inch overspray allowed on head and threads. After application of dry lubrication, the pin

outside diameter and sleeve inside diameter shall be lubricated with cetyl alcohol in accordance with

MIL-L-87132 or equivalent.

Unless otherwise specified, all dimensions are inches. Tolerances: Decimals ± .010, angles ± 2º.

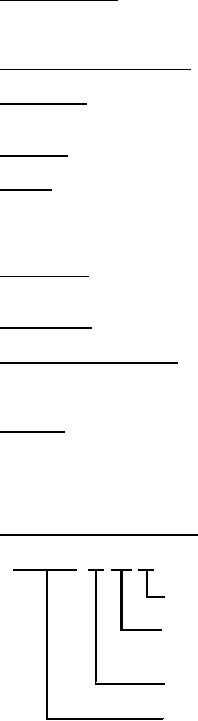

Example of military part number:

M85667/7 - 12 - 34

Grip length dash number in sixteenths of an inch. (Stamp on threaded end.)

` ` designates basic shank diameter: X designates 1st oversize, Y designates

2nd oversize. (Ink stamp on sleeve when applicable.)

Diameter dash numbers in sixteenths of an inch.

Basic specification sheet number.

10

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business